-

МОБИЛЬНЫЕ ТЕЛЕФОНЫ+86 13376920836

МОБИЛЬНЫЕ ТЕЛЕФОНЫ+86 13376920836 -

ПОЧТОВЫЙ ЯЩИКsales@cxplc.com

ПОЧТОВЫЙ ЯЩИКsales@cxplc.com

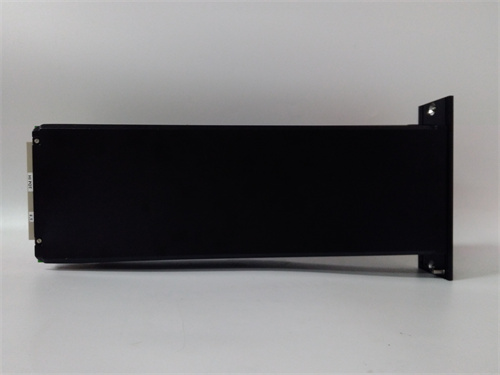

TRICONEX 8312

The TRICONEX 8312 is an advanced automation controller designed for high-reliability and critical applications. Part of the TRICONEX family, this model integrates seamlessly with various process control systems, ensuring optimal performance under demanding conditions. The TRICONEX 8312 is known for its robust architecture, capable of supporting multiple types of input/output configurations, and it heavily focuses on maintaining operational integrity.

With the TRICONEX 8312, users can expect superior safety and reliability. It features triple modular redundancy (TMR), which ensures that even in the event of a failure, the system can continue to function correctly. The TRICONEX 8312 is ideal for industries where the availability and safety of the processes are critical, such as oil and gas, chemical processing, and power generation.

The TRICONEX 8312 is widely used in various industries, including but not limited to:

In a recent deployment at an oil refinery, the TRICONEX 8312 was integrated into the safety instrumented systems (SIS) to monitor critical equipment and processes. The TMR capabilities ensured that any single point failure would not compromise the system's safety, leading to uninterrupted operations and adherence to regulatory standards.

Compared to other models like Siemens S7-1200 or Allen-Bradley ControlLogix, the TRICONEX 8312 stands out for its exceptional reliability due to its TMR design. While other PLCs might offer various features, the TRICONEX 8312 specifically focuses on high safety and reliability which are paramount in critical applications. Moreover, its extensive diagnostics and hot-swappable components set it apart in an industry that demands constant uptime.

When choosing a control system, consider the specific demands of your application. If your industry is subject to strict safety regulations and you require high availability, the TRICONEX 8312 is the best option. Evaluate your existing infrastructure to ensure compatibility with the communication protocols supported by the TRICONEX 8312, and assess your growth plans for scalability.

While using the TRICONEX 8312, it is essential to adhere to the manufacturer's guidelines to ensure system integrity. Regular maintenance checks and firmware updates can help in avoiding disruptions. It is also advisable to use certified personnel for installation and configuration to comply with safety standards.

We are your trusted partner; we provide the TRICONEX 8312 and other automation spare parts along with sales and technical support. We offer special discount prices for you. Please contact us, and we will be at your service.

Предыдущая статья :

TRICONEX 3511Следующий пост :

125768-01